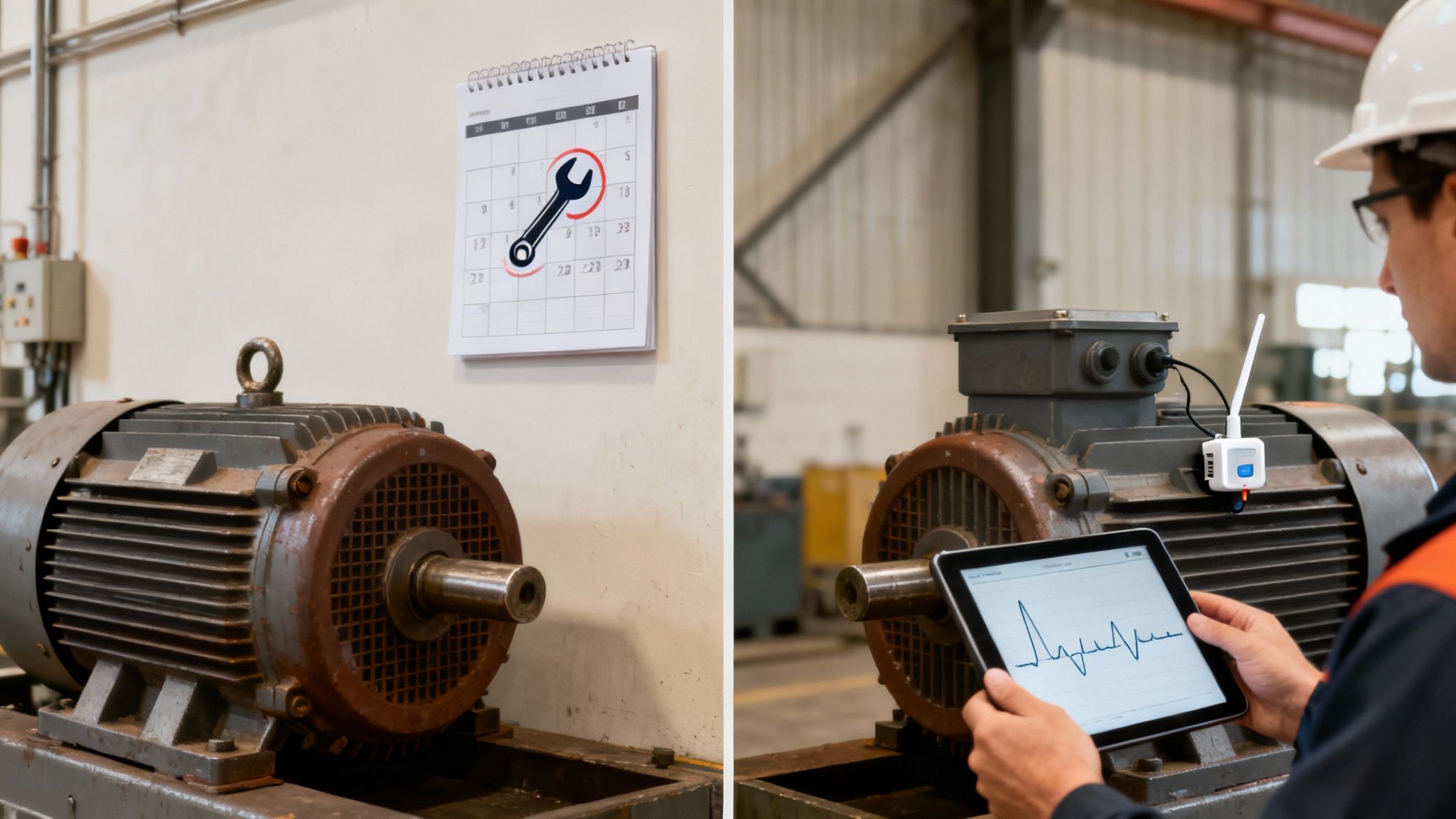

The core difference between predictive maintenance vs preventive maintenance is a shift from schedule-based actions to condition-based insights. Think of it this way: preventive maintenance is like changing your car’s oil every 5,000 miles, simply because the calendar says so. It’s a fixed, time-based routine. Predictive maintenance, on the other hand, is like using sensors that analyze the oil's quality, alerting you to change it at the exact moment it starts to degrade—no sooner, no later.

It’s a fundamental change in approach, moving from a "just in case" mindset to a "just in time" strategy that optimizes both equipment health and operational resources.

Choosing Your Industrial Maintenance Strategy

Selecting the right maintenance strategy is critical for ensuring operational reliability, especially for high-value assets like industrial motor controls. For years, preventive maintenance (PM) has been the industry standard. It provides a structured, calendar-based plan designed to reduce equipment failures by relying on historical data and manufacturer recommendations. It's a proven method for managing predictable wear and tear.

Predictive maintenance (PdM) represents a more dynamic, data-driven approach. By leveraging real-time data from tools like vibration sensors, thermal imaging, and oil analysis, PdM continuously monitors an asset's actual health. This allows maintenance teams to intervene precisely when needed—right before a failure occurs, but long after a scheduled PM task might have been performed unnecessarily. For a complete view of how maintenance fits into the larger asset lifecycle, it's helpful to understand the principles behind drone equipment lifecycle management.

Predictive vs Preventive Maintenance At a Glance

So, how do these two strategies truly compare? This table breaks down the core differences, making it easy to see the distinct advantages of each approach.

| Aspect | Preventive Maintenance (Time-Based) | Predictive Maintenance (Condition-Based) |

|---|---|---|

| Trigger | Fixed schedule (e.g., calendar days, cycles) | Real-time asset condition data |

| Data Reliance | Manufacturer specs and historical averages | Live sensor data and performance analytics |

| Cost Profile | Lower initial cost, potential for over-maintenance | Higher initial investment, lower long-term costs |

| Best For | Assets with predictable wear, lower criticality | Critical assets with complex failure modes |

Ultimately, neither strategy is universally "better." The optimal choice depends on the specific equipment, its role in your operations, and your organization's willingness to invest upfront to achieve greater long-term savings and reliability.

How Preventive Maintenance Actually Works

Preventive maintenance (PM) is built on a straightforward, time-tested philosophy: scheduled intervention is better than reactive repair. Rather than waiting for equipment to break, PM establishes a routine of inspections, component replacements, and servicing to prevent failures before they happen. It’s the foundational maintenance program for countless industrial facilities for good reason.

The entire PM system is driven by triggers that are predictable and easy to manage. These triggers are based not on the real-time condition of the equipment, but on predetermined intervals designed to address common wear-and-tear issues before they escalate.

Common Triggers for PM Tasks

- Calendar-Based: These are the simplest to implement. Tasks are performed on a fixed schedule—such as weekly inspections or annual overhauls—regardless of the equipment's usage.

- Usage-Based: This method ties maintenance more closely to actual operation. A task is triggered after a set number of operating hours, production cycles, or miles driven.

This time-or-usage approach makes PM highly effective for assets with well-understood failure patterns. For components like filters that predictably clog, belts that stretch with use, or lubricants that degrade after a certain number of hours, a scheduled replacement is an efficient and cost-effective way to maintain operational stability.

The primary drawback of preventive maintenance is its reliance on averages. It assumes components fail on a predictable schedule, which can lead to replacing parts that still have significant operational life, or worse, failing to prevent a premature failure that occurs before the next scheduled check.

For critical systems like Motor Control Centers, a robust proactive maintenance strategy is essential. You can dive deeper into mastering Motor Control Center maintenance to ensure these vital systems are managed effectively. While not flawless, this structured approach provides a strong first line of defense against common causes of downtime.

The Technology Behind Predictive Maintenance

Unlike the rigid calendar of preventive maintenance, predictive maintenance (PdM) functions as a real-time health monitoring system for your equipment. It uses live data to detect the earliest signs of a developing fault, enabling intervention at the optimal moment—not too early and not too late. This data-first approach is powered by advanced condition-monitoring technologies that provide a continuous, up-to-the-minute assessment of asset health.

At its core, PdM relies on a network of sensors collecting critical operational data. The process is clear: collect the information, analyze it with intelligent algorithms trained to identify failure patterns, and deliver precise alerts to maintenance teams. This strategy is ideal for complex and critical assets where failures, such as bearing faults or electrical insulation degradation, do not follow a predictable timeline.

Core Condition-Monitoring Tools

Several key technologies enable this real-time monitoring:

- Vibration Analysis: Specialized sensors detect subtle changes in vibration that often signal developing issues like shaft misalignment or bearing wear, long before they become catastrophic failures.

- Thermal Imaging: Infrared cameras are highly effective for identifying hotspots in electrical systems. A loose connection in a motor control center, for example, will appear as a thermal anomaly, indicating a significant fire or failure risk.

- Oil Analysis: Examining lubricant properties such as viscosity and particle contamination provides deep insight into an asset's internal condition, revealing hidden wear.

The true power of predictive maintenance is its ability to shift the conversation from "When is the next scheduled check?" to "What is this asset telling us right now?" It transforms maintenance from a recurring cost into a strategic, data-informed operation.

The rise of the Industrial Internet of Things (IIoT) has made this technology more accessible than ever. As more organizations engage in the predictive maintenance vs preventive maintenance discussion and adopt data-driven methods, the benefits become undeniable. Research shows that companies utilizing PdM can realize savings of 8% to 12% over purely preventive strategies. You can explore these figures and other maintenance statistics on WorkTrek.com.

Comparing Maintenance Costs and ROI

When evaluating predictive versus preventive maintenance, the conversation invariably turns to cost and return on investment (ROI). Both strategies aim to avoid the high cost of unplanned downtime, but they follow different financial paths. For any team responsible for managing a maintenance budget, understanding these distinctions is crucial.

Preventive maintenance offers a more accessible entry point. Its initial costs are primarily associated with labor, scheduling software, and maintaining an inventory of spare parts. This makes it an excellent starting point for facilities building a proactive maintenance culture. The downside, however, is that its rigid schedule can lead to inefficiencies, such as replacing components with remaining useful life or incurring labor costs for unnecessary tasks.

Analyzing the Financial Trade-Offs

Predictive maintenance, in contrast, requires a significant upfront investment in sensors, data acquisition systems, analytics platforms, and specialized team training.

While the initial outlay for a PdM program can be 3 to 4 times greater than a PM program, its long-term savings are substantial, often delivering 25% to 35% greater cost reduction over time. For a detailed breakdown, see this maintenance cost comparison on Oxmaint.com.

The higher ROI is generated by performing surgical, data-driven repairs that maximize asset life while eliminating unnecessary labor and material costs. A real-world example illustrates this clearly.

Scenario: A Critical Production Line Motor

Consider a critical motor on your primary conveyor system. How would each maintenance strategy approach its care?

- Preventive Approach: The maintenance plan mandates that the motor bearings be replaced every 12 months. This is a scheduled cost of time and materials, plus the planned downtime required for the replacement.

- Predictive Approach: Vibration sensors are installed to continuously monitor bearing health. After 18 months, the system detects a minor increase in vibration—the first sign of wear. The team receives an alert and schedules the replacement during the next planned shutdown, extending the component's life by 50% and avoiding both a premature replacement and the risk of a catastrophic failure.

The core financial difference is this: Preventive maintenance manages risk through scheduled spending based on averages. Predictive maintenance replaces that uncertainty with data, aligning every dollar spent with the real-time health of an asset. You only pay for maintenance when it is truly needed, maximizing long-term value.

Choosing the Right Maintenance Strategy

In the predictive vs preventive maintenance debate, the goal is not to choose a single winner but to build a smarter, more resilient maintenance ecosystem. The most effective industrial operations employ a hybrid strategy, applying the right technique to the right asset based on its criticality and failure predictability.

A practical starting point is to map your assets against two key factors: asset criticality and failure predictability. This allows you to allocate resources—budget, personnel, and time—where they will have the greatest impact on reliability and the bottom line.

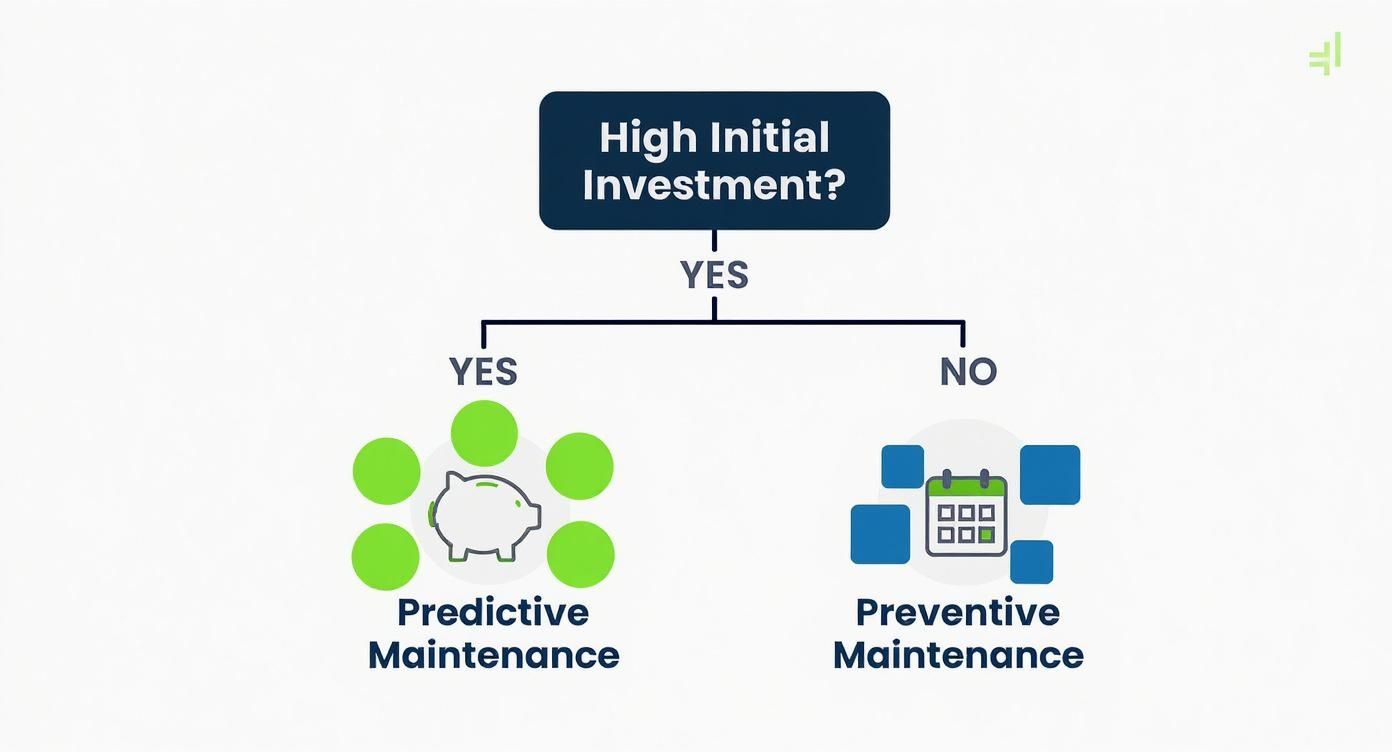

This simple decision tree can help visualize this choice, particularly when weighing initial investment against long-term returns.

As the flowchart indicates, while preventive maintenance has a lower entry cost, predictive maintenance offers a superior long-term ROI for those able to make the initial investment in technology and training.

Applying the Decision Framework

At its core, implementing this framework is straightforward. Analyze each piece of equipment to determine its optimal maintenance plan.

- High Criticality, Unpredictable Failures: These are your prime candidates for predictive maintenance. Consider a critical motor on your main production line; an unexpected failure would be catastrophic, justifying the investment in sensors and analytics.

- Low Criticality, Predictable Failures: For assets like HVAC filters or conveyor belts with known wear patterns, a low-cost preventive plan is ideal. A simple, scheduled replacement is more cost-effective than continuous monitoring.

A hybrid strategy isn't a compromise; it's an optimization. It allows you to leverage the cost-effectiveness of preventive maintenance for non-critical assets while safeguarding your most valuable equipment with the precision of predictive technology.

This blended approach delivers measurable results. A 2023 PwC study found that facilities using predictive maintenance reduced overall maintenance costs by 12% and increased asset availability by 9%. Furthermore, they extended the life of aging equipment by 20% compared to those relying solely on preventive methods. You can explore the full findings on the benefits of PdM from Upkeep. By combining strategies, you create a balanced, resilient system that optimizes both cost and performance across your entire facility.

A Few Common Questions

Even with a clear understanding of the differences between predictive and preventive maintenance, practical questions often arise during implementation. Here are some of the most common inquiries from industrial and maintenance teams. These insights can help you determine how each strategy fits within your real-world operations.

Can Predictive Maintenance Just Replace Everything We Do for Preventive Maintenance?

No, nor is it designed to. The most effective maintenance programs operate on a hybrid model. Predictive maintenance is the superior choice for high-cost, critical assets with complex failure modes, but traditional preventive maintenance remains the most cost-effective solution for simpler equipment.

Think of assets with predictable wear patterns, such as:

- Replacing HVAC filters on a quarterly basis.

- Changing conveyor belts after a set number of operating hours.

- Performing routine lubrication on non-critical machinery.

For components like these, the expense and effort of continuous monitoring do not provide a sufficient return. A simple, scheduled task is efficient and affordable, allowing you to reserve advanced analytics for the equipment that truly requires it.

What's the Single Biggest Hurdle to Getting Predictive Maintenance Started?

In most cases, the greatest barrier to adopting predictive maintenance is the initial investment. The upfront cost for sensors, data systems, analytics software, and team training can be significant. This initial expenditure is often a roadblock for organizations accustomed to established preventive schedules.

However, it is essential to view this as a long-term investment rather than a short-term expense.

For your most critical assets, the ROI from preventing a single catastrophic failure can often pay for the entire predictive maintenance system. Over time, the savings from reduced downtime, optimized labor allocation, and extended asset life consistently outweigh the initial setup cost.

How Do I Know if a Piece of Equipment Is a Good Fit for Predictive Maintenance?

Identifying the best candidates for predictive maintenance is key to maximizing your return on investment. A prime contender is any asset whose failure would cause a significant operational disruption, leading to major production losses and high emergency repair costs.

Look for assets that are:

- Operationally Critical: Its failure would halt a key production line or process.

- Complex in How They Fail: The asset has failure modes that are difficult to predict with a calendar or hour meter, such as bearing wear or insulation degradation in a large motor.

- Monitorable: It is possible to attach sensors to track key health indicators like vibration, temperature, or power consumption.

Perfect examples include large industrial motors, critical gearboxes, main transformers, and essential pumps. These are the assets where data-driven insights deliver real, measurable value.

At Kent Electrical Supply, LLC, we stock the high-quality motor controls, circuit breakers, and components that are the backbone of any solid maintenance strategy. Whether you're swapping a contactor on a preventive schedule or reacting to a predictive alert, we ship the parts you need the same day. Explore our inventory and get expert support at Kentstore.com.