Choosing the right contactor is key to ensuring dependable switching and protecting valuable machinery in tough industrial settings. This complete contactor selection guide gives businesses, electricians, and maintenance pros the expert knowledge they need on what a contactor is, how it works, and why precise sizing is crucial. You'll dive into core components, learn to tell contactors apart from relays and motor starters, explore different types—AC, DC, electromagnetic, solid-state, vacuum, latching, and definite purpose—and master specifications, duty cycles, and environmental factors. Brand comparisons highlight top manufacturers and certifications, while troubleshooting and maintenance tips help keep things running smoothly. Finally, discover key applications in motor control, lighting, heating, HVAC, renewable energy, and specialized uses, and understand when a motor starter is the better choice over a standalone contactor. By the end of this guide, you'll be confident in selecting industrial electrical contactors from kentstore.com that deliver safety, efficiency, and lasting reliability.

What Exactly Is a Contactor and How Does It Operate?

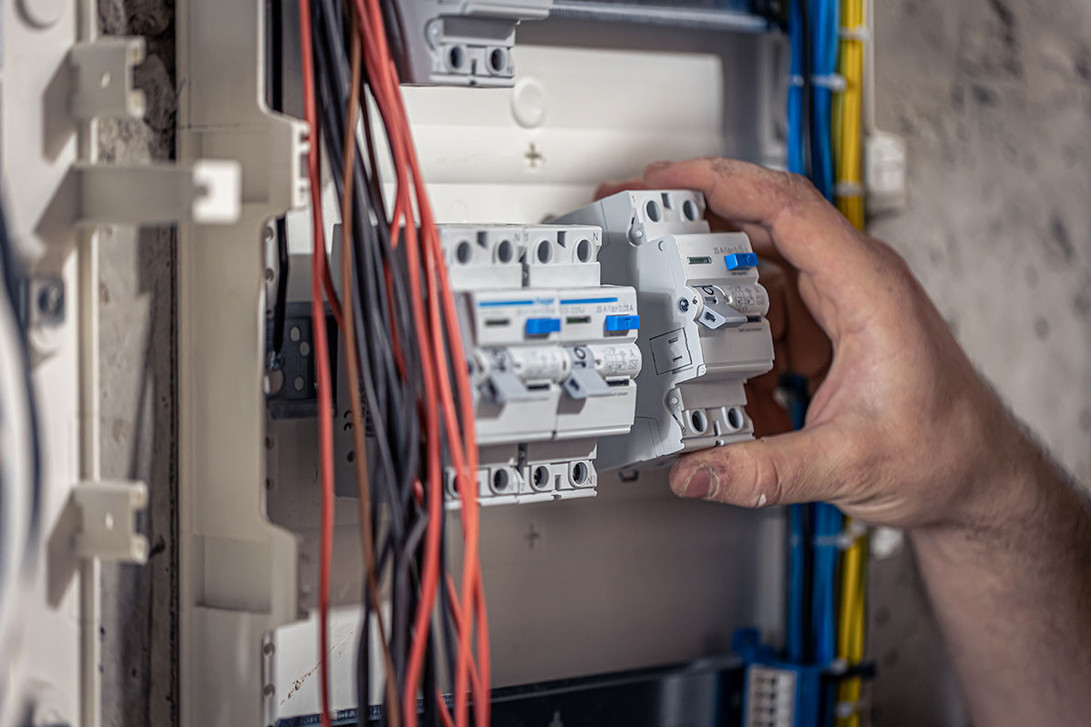

A contactor is essentially an electrically controlled switch designed to repeatedly open and close high-current circuits. It uses an electromagnetic coil to activate robust power contacts, ensuring safe and rapid switching in industrial systems. When the coil receives power, it generates a magnetic field that pulls a movable core, closing the power contacts and completing the circuit. When the coil is de-energized, the magnetic field collapses, and the contacts open, interrupting the current flow. This mechanism allows for automated control of motors, extensive lighting systems, heating elements, and other heavy loads, reducing wear on manual switches and significantly boosting operational safety.

Industrial control panels commonly feature contactors for managing motor starters, lighting circuits, and heating systems, consolidating power switching operations. As of October 2025, advancements in coil materials and arc suppression technologies have pushed mechanical lifespans well beyond ten million operations, making today's contactors ideal for continuous duty applications. Understanding this fundamental operating principle lays the groundwork for exploring individual parts, comparing similar devices, and mapping out real-world applications.

What Are the Primary Components of a Contactor?

A contactor is made up of three essential parts—the coil, the contacts, and the enclosure—all working together to efficiently switch and protect high-power circuits.

- Electromagnetic Coil: This component transforms electrical energy into a magnetic field. When energized, it pulls the armature, causing the power contacts to close.

- Power Contacts: Constructed from durable copper or silver alloys, these contacts carry the load current. They open and close under magnetic force, capable of handling high amperage with minimal resistance.

- Enclosure and Arc Chute: A sturdy housing protects the internal components from dust, moisture, and physical damage. The arc chute is designed to split and extinguish electrical arcs that form when the contacts separate.

These components work in harmony to ensure quick switching, a long electrical life, and safe operation. The coil's voltage rating dictates its compatibility with the control circuit, the contact materials determine the current-carrying capacity, and the enclosure's IP rating specifies its suitability for different environments. With these core parts in mind, it becomes clear why selecting the correct component specifications is vital for reliable performance.

How Does a Contactor Differ from a Relay and a Motor Starter?

A contactor is distinguished from a relay by its design for high-current switching—typically above 20 A—whereas relays are built for low-current signals, usually under 15 A. It also differs from a motor starter by not including built-in overload protection or integrated control circuitry. Relays utilize smaller coils and lighter contacts suitable for control signals, while contactors feature heavy-duty contacts designed for motors, heaters, and lighting loads. Motor starters, on the other hand, combine a contactor, a thermal or electronic overload relay, and start-stop control components to provide comprehensive motor protection and management.

This distinction is important when choosing the right device: contactors are ideal for straightforward switching tasks, relays excel in signal-level controls, and motor starters are designed for complete motor protection systems. Recognizing these functional differences directly informs the selection of the proper device for specific industrial applications.

What Are the Common Applications for Contactors in Industry?

- Motor Control: Used to start and stop three-phase and single-phase motors in systems like conveyors, pumps, compressors, and fans.

- Lighting Control: Manages large lighting arrays, streetlights, and high-bay fixtures, offering minimal downtime and remote operation capabilities.

- Heating Elements: Switches resistive loads found in industrial ovens, furnaces, and immersion heaters, providing precise timing and safety interlocks.

These applications benefit greatly from the fast switching, arc suppression, and mechanical durability that contactors offer. Within motor control panels, specialized AC-3 rated contactors are employed to handle the significant starting currents of motors, while lighting contactors, typically operating in the AC-1 category, are designed for resistive loads.

Exploring the Different Types of Contactors and Their Specific Uses

Contactors are categorized based on their load compatibility, operating principles, and application niches. You'll find options like AC, DC, electromagnetic, solid-state, vacuum, latching, and definite purpose contactors, each optimized to meet specific requirements. Every type is engineered to enhance performance for targeted uses, ranging from standard motor control to switching in challenging environments.

How Do AC Contactors Stack Up Against DC Contactors?

AC contactors are designed with alternating current coils and contacts specifically sized for sinusoidal voltages. In contrast, DC contactors feature direct current coils that generate a constant magnetic field, requiring more force to separate the contacts.

- AC coils benefit from the natural zero-crossing of voltage, which helps in interrupting the magnetic field and limiting arc duration.

- DC coils, however, need robust arc suppression mechanisms because the current doesn't naturally reach zero. This often involves magnetic blow-outs or specialized electronic arc chutes.

A DC contactor is the reliable choice for switching in battery systems, charging stations, and DC motor drives, whereas AC contactors are the standard for industrial motor starters, lighting, and heating controls. The decision between them hinges on the type of load, the voltage source, and how frequently the switching occurs.

This research highlights the distinct challenges and solutions for DC contactors, particularly concerning arc suppression and energy efficiency.

Zero-Holding-Energy Magnetic Contactors for Industrial Applications

"energy consumption down to zero. In modern energy efficient contactors holding energy. However, switching finishes fast, whereas the holding energy is consumed continuously for energy-efficient eco-friendly zero-holding-energy magnetic contactor for industrial and vehicular applications" - N Gabdullin, 2020

What's the Difference Between Electromagnetic and Solid-State Contactors?

Electromagnetic contactors utilize physical contacts that are moved by an actuated coil, offering low on-state resistance and high current handling capabilities. Solid-state contactors (SSCs), on the other hand, employ semiconductor devices for switching, meaning they have no moving parts. This results in silent operation and eliminates contact bounce.

- Electromagnetic: Known for their durability, cost-effectiveness, and suitability for frequent make-break cycles and high-current loads, sometimes reaching thousands of amperes.

- Solid-State: Offer rapid switching, minimal electromagnetic interference (EMI), and extended operational life. They are ideal for sensitive environments but come with a higher on-state voltage drop and require more attention to heat dissipation.

Electromagnetic contactors are the go-to for heavy machinery and established installations, while solid-state types are preferred for precision control, variable frequency drives, and situations where maintenance access is limited.

The nature of electrical arcs generated during contact separation is a critical factor in contactor lifespan and performance.

Arc Breaking Characteristics and Interruption Mechanisms in AC Contactors

"of breaking arcs are material erosion and its associated electrical contact failure. In this article, the ac arc of a commercial contactor is simulated experimentally and the relevant arc. Experimental investigation of the breaking arc behavior and interruption mechanisms for AC contactors" - Unknown Author, 2020

What Are Specialized Contactors Like Vacuum, Latching, and Definite Purpose?

Specialized contactors are designed to meet unique demands: vacuum contactors extinguish arcs within sealed ceramic chambers, making them suitable for high-voltage DC and arc-sensitive applications. Latching contactors can maintain their contact position without continuous coil power, significantly reducing control energy consumption. Definite purpose contactors are specifically designed for HVAC, refrigeration, and motor-pump combinations, often featuring compact designs and integrated accessories.

| Contactors | Key Characteristic | Typical Use Case |

|---|---|---|

| Vacuum | Sealed arc chamber | High-voltage DC, capacitor switching |

| Latching | Bistable operation | Energy-saving remote controls |

| Definite Purpose | Compact, accessory-ready | HVAC units, pumps, compressors |

These specialized designs extend contactor capabilities into environments where standard devices might not perform optimally, ensuring reliable switching under unique operational constraints.

How Do You Accurately Size a Contactor for Your Specific Application?

Properly sizing a contactor involves matching its electrical specifications and operational requirements—including voltage, current, coil voltage, contact configuration, load type, duty cycle, environmental conditions, and expected lifespan—to ensure safe, efficient performance and maximum service life.

What Are the Key Electrical Contactor Specifications You Need to Consider?

The voltage rating, current rating, and coil voltage are the primary attributes that determine a contactor's compatibility with your power and control circuits.

- Voltage Rating: This is the maximum line voltage the contacts can safely interrupt.

- Current Rating: This indicates the continuous current capacity under specified temperature conditions and utilization category.

- Coil Voltage: This is the control circuit voltage required to energize the coil. It's commonly available in both AC and DC versions.

Ensuring these specifications align correctly prevents overheating, premature contact wear, and failures in the control circuit. Your selection process must also account for inrush currents, voltage spikes, and any de-rated performance that might occur at high altitudes or elevated temperatures.

How Do Load Type and Duty Cycle Influence Contactor Selection?

Different load types, such as resistive and inductive, draw varying amounts of current and place different mechanical demands on the contactor. These are categorized by IEC utilization classes (e.g., AC-1 for resistive loads, AC-3 for motor starting). The duty cycle specifies how often and for how long the contactor is expected to operate.

- Resistive (AC-1): These loads draw constant currents with minimal arc generation, making them suitable for heaters and lighting.

- Inductive (AC-3): These loads, like motors, experience high inrush currents during startup, requiring robust contacts and effective arc suppression.

Duty cycle considerations—whether it's intermittent, continuous, or heavy-duty—will influence the required coil insulation class, the expected mechanical life, and the necessary cooling provisions. Matching the load category and duty cycle is essential for ensuring contact durability and overall system reliability.

What Role Do Contact Configuration and Auxiliary Contacts Play?

The contact configuration determines the number of power poles and auxiliary contacts (both normally open and normally closed) available for signaling, interlocks, and control logic.

- Poles: Arrangements like two-pole, three-pole, and four-pole are available to accommodate single-phase and three-phase systems.

- Auxiliary Contacts: These provide crucial functions such as remote status feedback, safety interlocks, and interlocking between contactor coils.

Selecting the correct configuration can streamline control circuit design and enable advanced automation features, including interlocked starts, sequential contactor operations, and motor reversal.

How Do Environmental Factors and Lifespan Influence Sizing Decisions?

Factors such as ambient temperature, humidity, the presence of corrosive atmospheres, and the contactor's mechanical life ratings directly impact its performance and longevity.

- Temperature Range: Both coils and contacts must be able to withstand the expected operating temperature extremes without significant derating.

- Ingress Protection (IP) Rating: This rating indicates how well the enclosure shields the internal components from dust, water, and other contaminants.

- Mechanical and Electrical Life: These are typically specified in millions of operations and are crucial for planning maintenance schedules and spare parts inventory.

Choosing contactors with robust enclosures, coils designed for high temperatures, and corrosion-resistant contacts can significantly extend their service life, especially in harsh conditions, thereby minimizing unplanned downtime and replacement costs.

Which Industrial Contactor Brands Stand Out and Why?

Top contactor manufacturers consistently deliver quality, innovation, and extensive global support networks, ensuring reliability and adherence to international standards. Evaluating these brands can help you align your specific needs with proven performance histories.

Who Are the Leading Manufacturers of Industrial Contactors?

Brands like Schneider Electric, ABB, Eaton, and Siemens are major players in the industrial contactor market, offering extensive product lines, comprehensive global support, and robust distribution channels.

- Schneider Electric's TeSys range is recognized for its focus on energy efficiency and modular accessories.

- ABB provides compact designs that boast high mechanical life ratings.

- Eaton offers versatile product families designed for demanding, harsh environments.

- Siemens integrates advanced diagnostic capabilities with built-in safety features.

The choice among these leading brands often depends on the specific application requirements, the availability of local service and support, and the manufacturer's long-term commitment to customer assistance.

How Do Certifications and Quality Standards Affect Brand Selection?

Certifications from organizations like UL, CE, and adherence to IEC standards serve as validation of a product's compliant design, safety, and performance under standardized testing conditions.

- UL Listing: This signifies approval for safety in the North American market for electrical devices.

- CE Marking: Indicates conformity with essential European health, safety, and environmental protection directives.

- IEC Standards (e.g., 60947-4-1): These standards define crucial parameters such as utilization categories, dielectric test values, and mechanical endurance requirements.

Brands that hold a broad range of certifications can ensure smoother integration into global installations, simplify approval processes, and reinforce confidence in the product's overall reliability.

How Do Brand Innovations Enhance Energy Efficiency and Reliability?

Manufacturers are continually innovating. Features like electronic coils significantly reduce idle power consumption, compact designs simplify panel layouts, and integrated diagnostic modules provide alerts for predictive maintenance.

For instance, Schneider Electric's TeSys Deca Green electronic coil technology can cut coil power consumption by over 50 percent, leading to reduced control circuit losses and less heat buildup. Such advancements not only extend equipment life but also lower energy costs and streamline troubleshooting efforts.

How Can You Troubleshoot and Maintain Contactors for Peak Performance?

Maintaining consistent productivity relies on your ability to identify failure symptoms, apply systematic diagnostic procedures, and practice preventative maintenance to avoid unexpected downtime.

What Are the Most Common Contactor Problems and Their Symptoms?

Issues like contact oxidation, coil burnout, contact welding, and pitted contact surfaces are frequent challenges, each presenting distinct symptoms:

- A humming or buzzing sound often indicates irregularities with the coil voltage.

- Excessive heat at the terminals can signal loose connections or an overloaded condition.

- A failure to pull in or drop out typically points to coil damage or faults within the control circuit.

- Visible arcing or carbon buildup on the contacts suggests inadequate arc suppression.

Recognizing these symptoms early allows for targeted corrective actions before secondary equipment damage can occur.

How Do You Test and Diagnose Contactor Issues?

Testing involves verifying coil continuity, contact resistance, and control voltage levels using essential tools like a multimeter and a clamp meter.

- Measure the coil resistance and compare it against the manufacturer's specifications to detect open or short circuits.

- Check the contact resistance under no-load conditions; excessively high values indicate contact degradation.

- Confirm that the correct control voltage is present at the coil terminals during operation.

- Visually inspect the mechanical movement to ensure smooth armature travel.

These diagnostic procedures are effective in pinpointing electrical and mechanical faults, guiding decisions on component replacement or necessary adjustments.

What Are the Best Practices for Preventative Maintenance?

Routine inspection and cleaning are crucial for keeping contactors operating at their best. This involves removing dust, debris, and corrosion, as well as verifying that all electrical connections are tight.

- Schedule biannual visual inspections to check for enclosure integrity and signs of contact wear.

- Use appropriate contact cleaner to remove debris without leaving any residue.

- Ensure terminal screws are tightened to the manufacturer's specified torque values.

- Replace coils and auxiliary contact modules at the intervals recommended by the manufacturer.

Implementing preventative maintenance programs, tailored to the specific duty cycle and ambient conditions, can significantly minimize unexpected failures and extend the operational lifespan of your contactors.

What Are the Key Industrial Applications for Contactors?

Contactors play a vital role as critical switching elements across a wide spectrum of industrial systems—from motor starters to renewable energy installations—providing safe and reliable control over electrical power.

How Are Contactors Utilized in Motor Control Systems?

Within motor control panels, contactors are essential for managing the substantial inrush currents that occur during the start-stop operations of three-phase and single-phase motors. They work in conjunction with overload relays, programmable logic controllers (PLCs), and variable frequency drives (VFDs) to achieve precise speed and torque management. Motor control contactors specifically rated AC-3 are optimized for frequent motor starts and stops, ensuring minimal contact wear and consistent performance under cyclical loading conditions.

What Role Do Contactors Play in Lighting and Heating Controls?

Lighting contactors, often rated AC-1, are used to switch large banks of fluorescent, LED, and HID fixtures, enabling synchronized timing across multiple circuits. Heating contactors are employed to manage resistive loads in industrial ovens, kilns, and process heaters, providing safe on/off cycling with minimal stress on the contacts. These applications rely heavily on effective arc chutes and optimized contact materials to ensure an extended service life, even with frequent switching.

How Are Contactors Applied in HVAC and Renewable Energy Systems?

HVAC systems frequently utilize definite purpose contactors, which often come with built-in accessories designed for compressor and fan controls, facilitating efficient temperature regulation and energy savings. In renewable energy setups, such as solar inverters and battery storage systems, DC contactors are incorporated to safely isolate high-voltage arrays. These DC contactors leverage advanced arc suppression and vacuum switching technologies to protect sensitive semiconductor equipment.

What Are Examples of Contactors in Capacitor Switching and Other Niche Uses?

Switching capacitor banks, a common task in power factor correction, requires vacuum contactors capable of effectively quenching arcs at high voltages, thereby preserving capacitor health and overall system performance. In material handling applications, latching contactors are used to maintain load status even during power interruptions, without requiring continuous coil power, which significantly reduces control energy consumption. For challenging environments, specialized contactors with stainless-steel enclosures and conformal coatings are available to ensure reliable operation in marine, mining, and chemical processing settings.

What Are the Key Differences Between Contactors and Motor Starters?

While contactors are designed for pure switching capabilities, motor starters integrate contactors with essential protective elements and starting controls, offering a complete motor management solution. Understanding their distinct roles is crucial for making the right choice for your specific operational needs.

How Does a Motor Starter Integrate a Contactor and Overload Protection?

A motor starter typically combines an electromagnetic contactor with a thermal or electronic overload relay. Many also include integrated start-stop pushbuttons, pilot lights, and control transformers. The overload relay continuously monitors the motor's current draw against pre-set thresholds. If excessive current persists, it trips the contactor coil, effectively protecting the motor windings from overheating and preventing mechanical damage.

When Should You Opt for a Contactor Versus a Motor Starter?

You should choose a standalone contactor when your application requires simple on/off switching for high-current loads and does not need integrated motor protection, such as in lighting or heating circuits. Conversely, opt for a motor starter when your application demands both switching capabilities and overload protection for electric motors. This ensures safe starting under heavy inertia and safeguards against conditions like locked rotors or prolonged stall situations.

What Are the Safety and Reliability Implications of Each Choice?

Using a motor starter provides built-in motor protection, significantly reducing the risk of overheating and equipment failure, and often helps meet safety regulations for motor installations. Standalone contactors, while versatile, require external protective devices like fuses or circuit breakers, which can introduce additional complexity and potential points of failure. Integrating motor starters simplifies wiring and compliance, whereas contactors offer greater flexibility for various load types when protection is managed separately.

Selecting the appropriate contactor or motor starter is fundamental to optimizing system safety, reliability, and maintenance efficiency in industrial environments.

Choosing the right industrial contactor or motor starter hinges on precisely matching the device's characteristics to the load demands, environmental conditions, and control system architecture. By thoroughly understanding operating principles, component functions, available types, sizing guidelines, brand reputations, troubleshooting techniques, and specific application nuances, you can make informed decisions that maximize uptime and operational efficiency. Partner with kentstore.com to explore a comprehensive selection of certified contactors, essential accessories, and motor control solutions—all backed by expert guidance and tailored to meet your exact specifications.